Excavation accuracy system on behalf of Guy Engineering Systems

Excavation precision system and professional language MACHINE CONTROL is an advanced system that uses technology to analyze the area and control excavations in a precise and efficient manner.

The system makes use of various sensors and advanced antennas installed on mechanical engineering equipment, to enable measurement and digging of canals, alignment of plots and work in parallel with engineering teams and according to work plans.

The main system components:

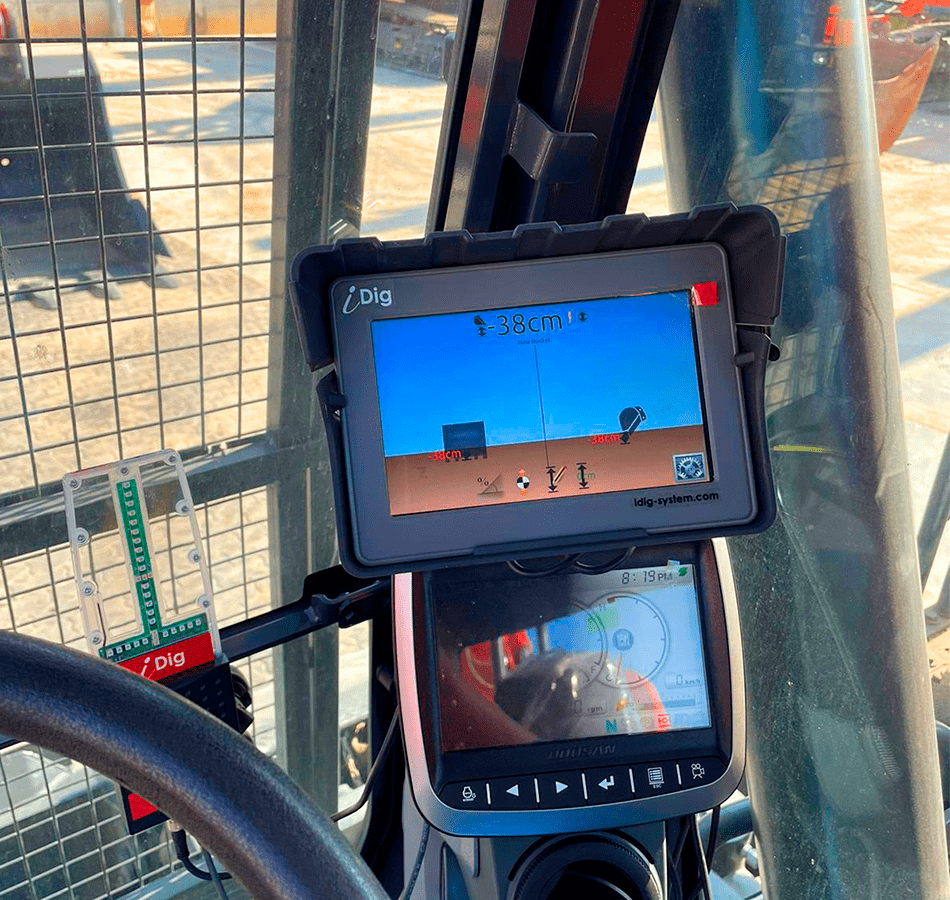

1. Local indication: A local indication system allows the user to clearly see the position and condition of the tool and the excavation in real time. This allows the operator of the tool to easily determine the location required for digging and synchronize the operations of the digging tool accordingly.

2. Navigation system: A navigation system is used to link the current location of the tool and the excavation to the general geographic information system. This allows the tool operator to create an accurate excavation plan and manage the operations on the right track.

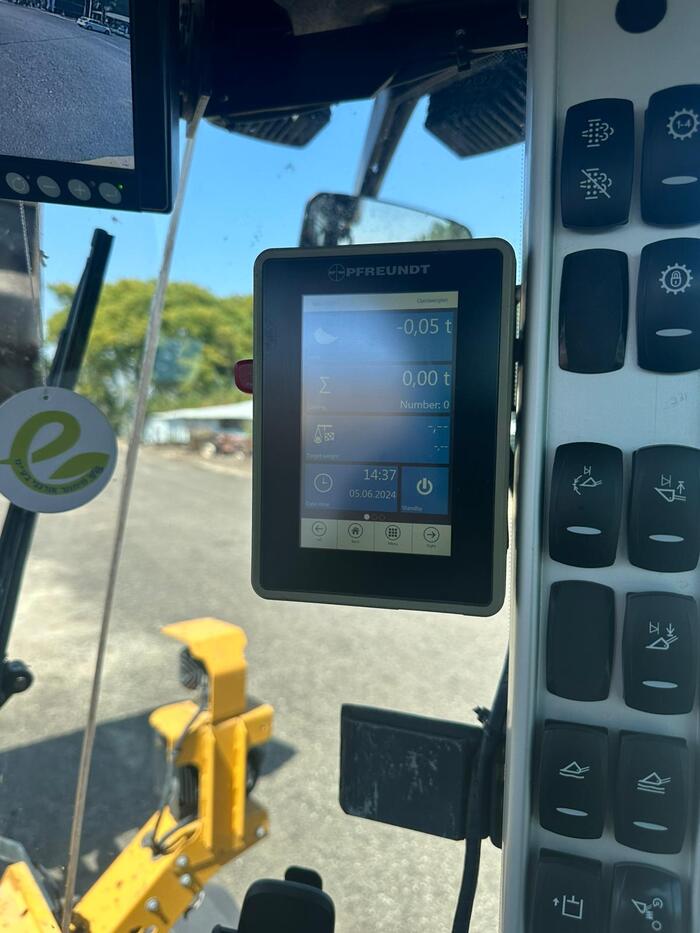

3. Laser scanners: The laser scanners are used to measure and accompany excavations. They are able to create a three-dimensional model of the structure of the excavation and provide precision information about the height, width and depth of each point in the structure.

4. Data analysis system: A data analysis system allows to process and analyze the information collected from the excavation. This allows the operator of the tool to identify and decipher the main features of the excavation and determine the appropriate actions to continue the work.

Ways to determine the location required for digging:

1. Accurate navigation:

- The navigation system in the MACHINE CONTROL system that allows the tool operator to see the current position of the tool in real time in relation to the desired position.

- The system uses information from geographic systems, such as GPS systems, and through GNSS type antennas with maximum accuracy to provide accurate information on the current location of the tool and this allows the operator to focus on the place required for excavation and adjust the operations in the field accordingly.

2. Accurate geographic information:

- The system uses various sensors installed on the excavation tools to provide a real-time snapshot of the required depths from the entered work plan and at the same time collects accurate geographic information about the structure of the excavation: the information includes height, depth and width data of each point in the excavation – the tool operator synchronizes the location required of the excavation in relation to the current location of the tool.

3. The machine operator’s job is to enter the excavation data on a friendly and easy-to-use touch screen in the driver’s cabin, the desired depth, the angle of inclination, or enter the data using a mobile device and start the excavation

4. We commit to shortening work processes and significant personnel and maximum accuracy in digging!

The precision system in excavation MACHIN CONTROL is an essential tool for improving accuracy and efficiency in excavation processes.

With a combination of local indication, an advanced navigation system, laser scanners and a data analysis system, the system provides a comprehensive and reliable solution for accurate and effective excavation management.

For additional questions or if you are interested in more details about the system, please contact us and we will be happy to provide you with a professional service.